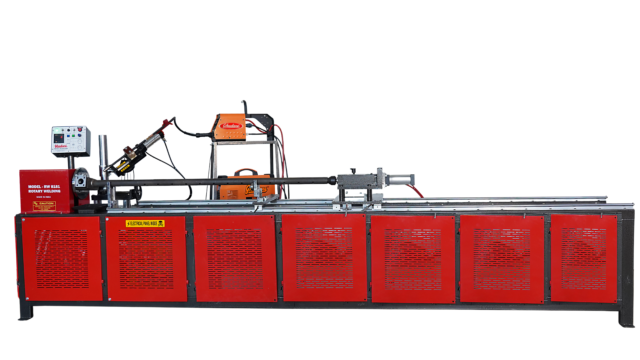

HomeInner Prop Welding Machine

Inner Prop Welding Machine

Features: High production, easy to operate, easy to maintain, uniform welding results, Inbuilt Mig Welding, Length Adjustment, USA make Mig Touch.

Description: Automatic Inner prop welding machine is helpful to weld base plate with pipe and does not make any joint between them. It raises the production rate and provides uniformity to the product. Inner prop is used in combination of Outer prop welding to make a structure. All the components are used in combination of each other-Base jack welding machine, Inner prop welding machine, Outer prop welding machine, Cup lock welding machine, and Ringlock welding machine.For swift production and consistent results, this system is based on circular welding on both base plates with pipe and pipe from both positions.

| Drive | A.C. Motor with V.F.D |

| R.P.M. | 2 to 12 |

| Motor | 0.5 H.P., 1440 R.P.M. |

| Operation | Automatic |

| Air Pressure Required | 4 to 5 Bar |

| Length Adjustment | 500 to 3000mm |

| Power | 1 Phase, 220 Volts ±5% |

| Required SPM | 0.5 K.V.A. |

| Power | 3 Phase, 415 Volts ±5% |

| Required Mig Welding | 9×2 = 18 K.V.A. Max. |

| Frequency | 50/60 H.Z. |

| Operating Voltage | 24 Volts |

| Control | PLC with Touch Screen/Digital |

| Production | 400-450 Approx. |

| Dimensions | 14(L) x 2.8(W) x 6(H) Feet Approx |

| Weight | 900 Kgs.(Approx.) |