HomeAutomatic Painting Conveyor For Scaffolding

Automatic Painting Conveyor for Scaffolding: Streamlining Finishing Processes

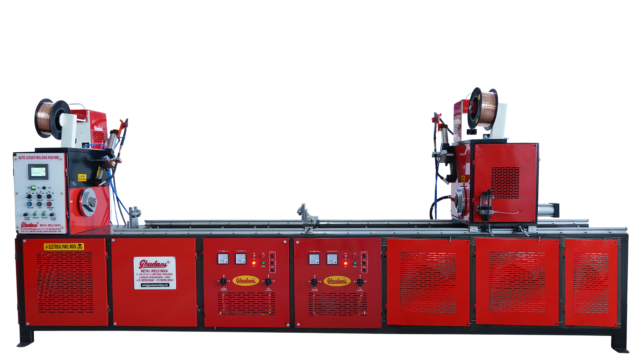

Ghudani Welding Works manufactured scaffolding dip painting Conveyor. This is very useful for Scaffolding Standard Cuplock painting, scaffolding Ledger Painting, scaffolding prop painting, scaffolding walkboard painting, scaffolding plank painting. In this Uniform paint coating and good finish.

Explore the future of scaffolding finishing with our Automatic Painting Conveyor, a cutting-edge solution designed to elevate efficiency and precision in the painting and coating of scaffolding components. Engineered for seamless integration into production lines, this conveyor system ensures a uniform and high-quality finish on every scaffolding structure.

Crafted with innovation in mind, the Automatic Painting Conveyor offers a range of features to optimize the painting process:

Versatile Conveyor Design: The conveyor is adaptable to various scaffolding sizes and shapes, providing versatility in handling different components. This design flexibility ensures comprehensive coverage during the painting process.

Automated Painting System: Embrace automation for consistent and controlled painting. The system is designed to automate the application of paint, reducing manual labor and ensuring an even coating on every surface.

Variable Speed Control: Tailor the painting process to different requirements with variable speed control. Adjust the conveyor speed based on the type of scaffolding and coating specifications for optimal results.

Efficient Drying Mechanism: The conveyor includes an efficient drying mechanism to expedite the curing process. This feature ensures a quick turnaround time, allowing for increased production efficiency.

Integrated Safety Features: Prioritize workplace safety with integrated safety features. The Automatic Painting Conveyor is equipped with safety mechanisms to protect operators and maintain a secure working environment.

Customizable Configuration: Tailor the conveyor system to meet your specific production needs. The customizable configuration allows for integration with existing production lines, ensuring a seamless workflow.

Remote Monitoring and Control: Stay in control of your painting processes with remote monitoring capabilities. Monitor the conveyor system and make adjustments remotely for enhanced operational convenience.